INFRASTRUCTURE

The department has evolved a comprehensive student-centric learning approach, designed to add significant value to the learner’s understanding in an integrated manner through workshops, lab sessions, assignments, training, seminars, projects and independent study. The hands-on training offered in laboratories training in latest equipment’s and design software brings in a formal method of familiarizing with the industrial practices helps the students to apply their class room knowledge to live industrial situations. As a part of their Autonomous Curriculum students develop mini projects in various domains during their graduation stay. Students are also permitted to work on authorized software to facilitate their final year projects.

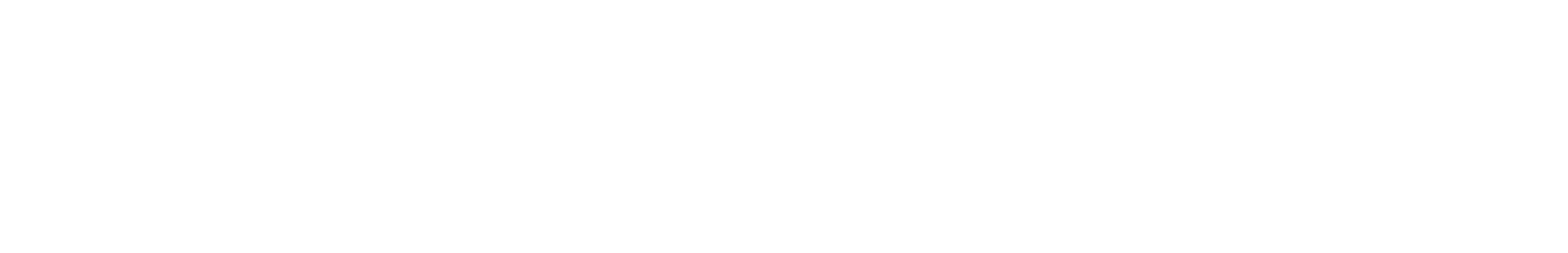

NON CONVENTIONAL ENERGY RESOURCE LAB

“I would put my money on the sun and solar energy. What a source of power! I hope we don’t have to wait until oil and coal run out before we tackle that.” Thomas A Edison.

With rampant power cuts in the city, institutes are increasingly looking at alternative solutions to manage their power needs. In one such effort, a solar plant has been installed by Department of Mechanical Engineering, New Horizon College of Engineering. The 30kW solar photovoltaic system was set up at Sardar Vallabhbhai Patel block. The power from the solar PV system is currently being supplied to all Class Rooms & laboratories in the block. Since solar energy is being promoted in India in a big way, with government targeting 1.75GW of renewable power and an investment of 100 billion dollar by 2022 thus making it essential to study the performance of solar panels under varying climatic conditions for realizing the potential of solar power. Replacing traditional sources of energy completely with renewable energy is going to be a challenging task. However, by adding renewable energy to the grid and gradually increasing its contribution, we can realistically expect a future that is powered completely by green energy.

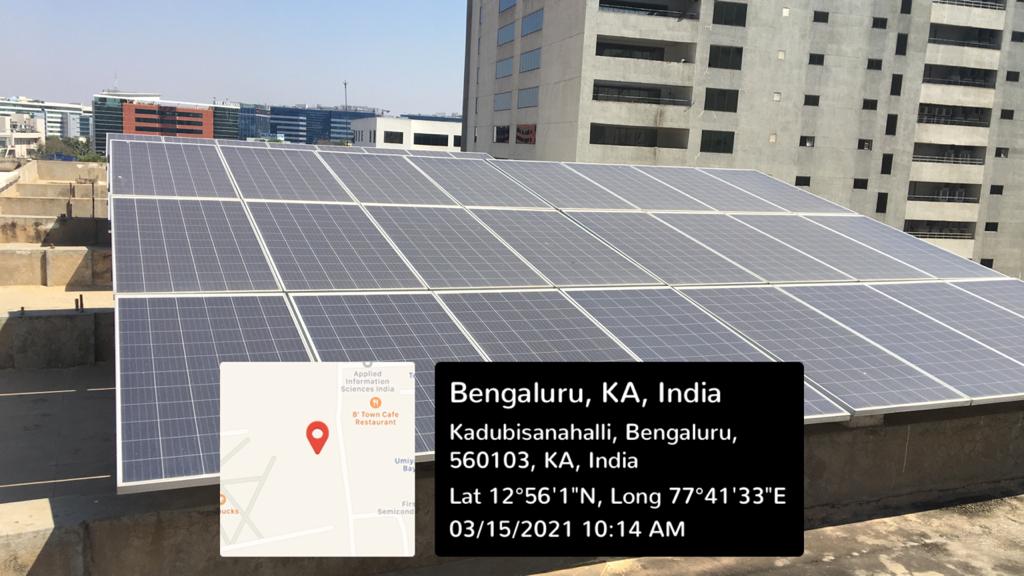

FUNDAMENTALS OF HEAT TRANSFER LABORATORY

The experiments in the heat transfer laboratory help the students to understand all the 3 modes of heat transfer, namely conduction, convection and radiation practically. These experiments also pave way for inculcating certain innovative skills in the students making them to use the above experimental setups as starting point to take up higher level experimental studies in Heat Transfer. Experimental facilities include setups for measuring thermo-physical properties of insulation materials, building materials, gases and liquids. Performance of different types of heat exchangers can also be evaluated.

MECHANICAL MEASUREMENTS & METROLOGY LABORATORY

The general idea of metrology is (metrological) traceability, defined as “the property of the result of a measurement or the value of a standard whereby it can be related to stated references, usually national or international standards, through an unbroken chain of comparisons, all having stated uncertainties.” The level of traceability establishes the level of comparability of the measurement: whether the result of a measurement can be compared to the previous one.

Metrology laboratory is a very important part to the education and research efforts in different areas of engineering with wide variety of high-end measurement instruments. Apart from the academic requirements, the facilities are capable of supporting necessary activities related to scientific or fundamental metrology, applied or industrial metrology and legal metrology. The capabilities of this laboratory include a wide variety of coordinate metrology, surface finish and various traditional dimensional metrology instrumentations. It is meant to impart basic knowledge of different sensors used for mechanical measurements. In this laboratory the linear displacement measurement is demonstrated by LVDT, Inductive Pick up Strain Gauge based cantilever, the load measurement by load cell and strain gauge based cantilever and the temperature measurement by RTD Thermistor and Thermocouple.

MACHINE FOR MANUFACTURING TECHNOLOGY LAB

It is a central facility equipped with various traditional and non-traditional machines for manufacturing products. It also has various modern machines such as rapid prototyping machines. This central facility is available for design and manufacturing of products to all the faculty and students of all the departments. Here, various interesting projects of which some of them are patented have been developed.

ADVANCED MANUFACTURING LABORATORY

It was established with emphasis to provide hands-on-experience to students in Production and Fabrication of simple mechanical components. Students will be exposed to different methods of manufacturing, materials and components, as well as procedures currently used in commercial manufacturing and assembly processes. This will be of immense help in transforming students to engineers. Besides, the state-of-the-art facilities developed under the roof of the Workshop is also extended to research scholars to perform novel and cutting edge research. Research: Research in machining is also carried out by several Ph.D. students in this facility.

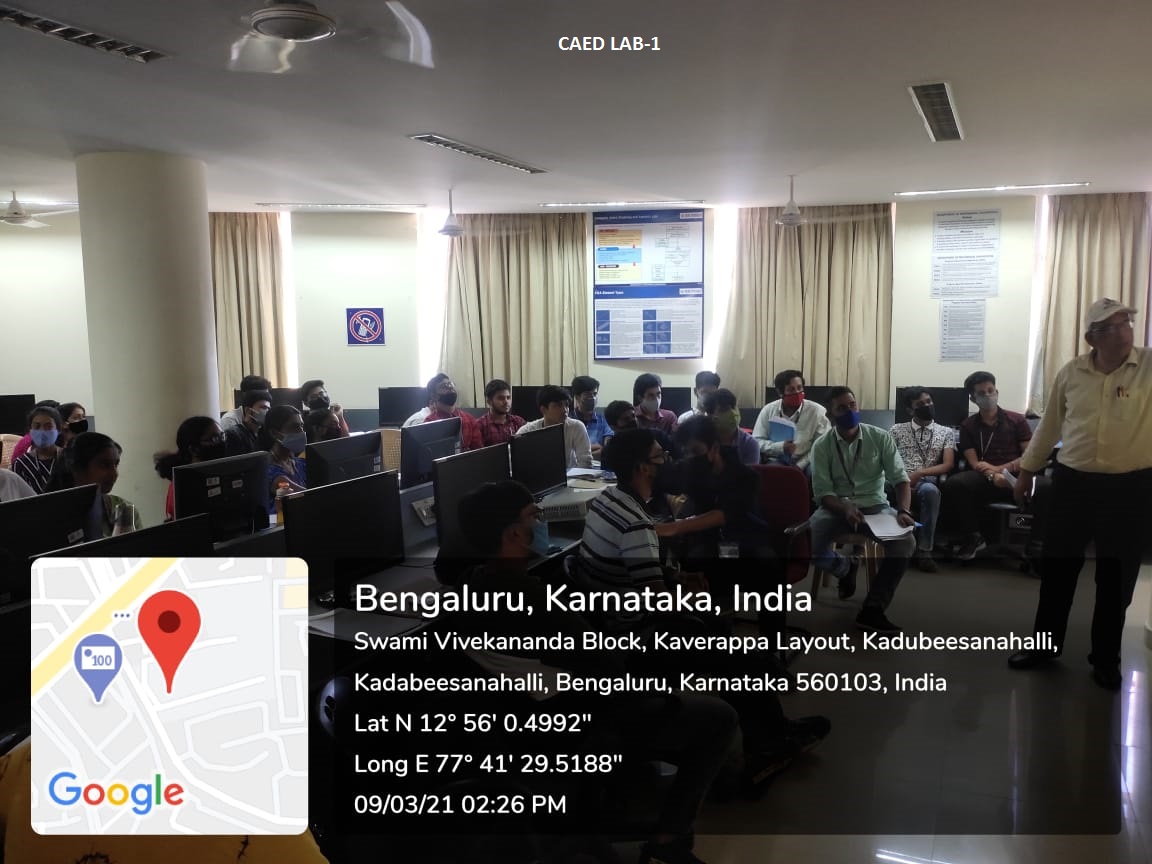

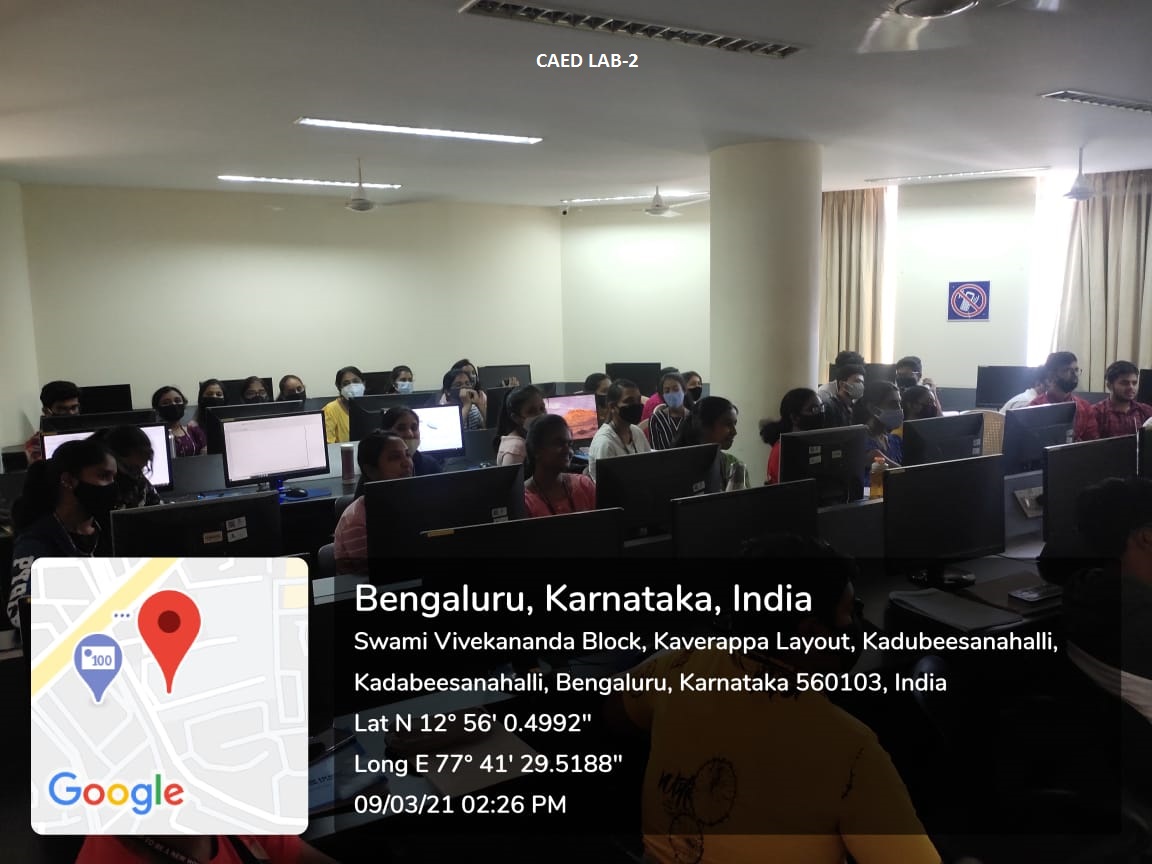

COMPUTER AIDED ENGINEERING DRAWING LABORATORY

The research and development for products with better design and higher quality is now a dominant factor of competition among many industries. This trend is supported by the introduction and successful implementation of modern computer technologies for product design. The high quality and technologically advanced products and services are the end result of integration of a series of processes and functions which are present in every enterprise, e.g. research, design, manufacture, maintenance, marketing etc. Computer Aided Design (CAD) laboratory is developed with a view to train students to manage and execute the integration of all these different components.

MATERIAL SCIENCE & METALLURGY LABORATORY

The Metallography laboratory has been conceptualized as the starting block of material research in terms of sample preparation and analyzing the mechanical properties of material. This facility will be helpful to prepare specimens capable of revealing the true microstructure of materials submitted for study. The laboratory would be capable of performing simple microscopic evaluations, linear measurements, and other related tests. To provide the services required, a Metallography section has been knowledgeably organized, adequately equipped and competently staffed.

MECHANICAL VIBRATION & MTMD LABORATORY

Design of Machines introduces the Mechanical Engineering student to the motion and interaction of machine elements. Fundamental concepts of statics, kinematics, and dynamics will be applied to the determination of the motion and interaction of machine elements, as well as forces acting on machines and mechanisms. Specific applications will be made to mechanisms such as rotating machinery, cams, gears, flywheels, and balancing. The emphasis is on studying the motion of machines by analyzing and synthesizing mechanisms and machinery. It provides the mechanical engineering student the foundations necessary to design and develop various machine and mechanism components. Kinematics and dynamics of machines laboratory is one of the essential part of the education and research activities in different areas of engineering with wide range of equipments and educational kits. Apart from the academic desires, the laboratory facilities are capable of demonstrating and validating various mechanisms and machines related to scientific or fundamental research related to machine design.

FLUID MECHANICS AND ROTOR DYNAMICS LABORATORY

The Fluid Mechanics and Machinery laboratory is an integral part of Mechanical Engineering studies in mechanical department. It covers measuring devices and techniques, error analysis in experimental works, analysis of assumptions and application of the theories of fluid mechanics. It is an introductory course where flow behaviour, fluid forces and analysis tools are introduced. The goals of the experiments include determining the forces generated when fluid flow takes place over a solid object, applications of the control volume approach, demonstration of the momentum and energy equations, and engineering correlations. Intricate flow phenomena such as separations and transition to turbulence are demonstrated. Experimental setups such as flow through a tube, flow over a flat plate, are made available to the students. The laboratory experiments utilize U-tube manometer and digital manometer, data acquisition. The laboratory runs closely with the lectures in such a way that experiments support the text covered in the class room.

CASTING FORGING AND JOINING TECHNOLOGY LABORATORY

The foundry and forging laboratory initiated its role of transforming students to engineers capable of thinking, designing and executing new ideas and has already achieved considerable success. It has provided infrastructure and service to the faculty members/research scholars to fabricate (casting) experimental model for research/consultancy purposes and helping the UG/PG students in designing their projects. Research scholars are now capable of custom designing their experimental model to produce their desired results. The foundry and forging laboratory provides excellence and problem specific solutions to industries and research organization, apart from teaching students on handling the facilities.

WORKSHOP LABORATORY

The workshop Facilitates to impart practical skills for the students in major fields of engineering and technology. It also helps to fabricate experimental set up with the required quality and quantity within stipulated time to support research projects of the Institute. The workshop is capable of meeting with three major production processes, i.e. metal cutting, metal joining and metal forming in various shops like-Fitting shop, Welding Shop, Sheet metal shop. These shops were established in the process of modernizing the workshop training in line with industry to suit industrial requirements.

HEAT POWER CYCLE LABORATORY

Energy Conversion laboratory mainly focus on Engines Performance, Emissions and Combustion characteristics of various engines by using conventional fuels, different alternate bio-fuels, Engine combustion diagnostics, fuel properties such as viscosity, flash point, fire point, calorific value and other engines related research and consultancy works through Experimental and Computational work. R & D activities related to utilization of alternative fuels are being pursued in this laboratory. Fuels that are being investigated include Biodiesel, Ethanol and Methanol. The laboratory is equipped with test rigs and instruments to evaluate the performance, emissions and combustion characteristics of the system fuelled with these alternative fuels or their blends with conventional petrol and diesel.

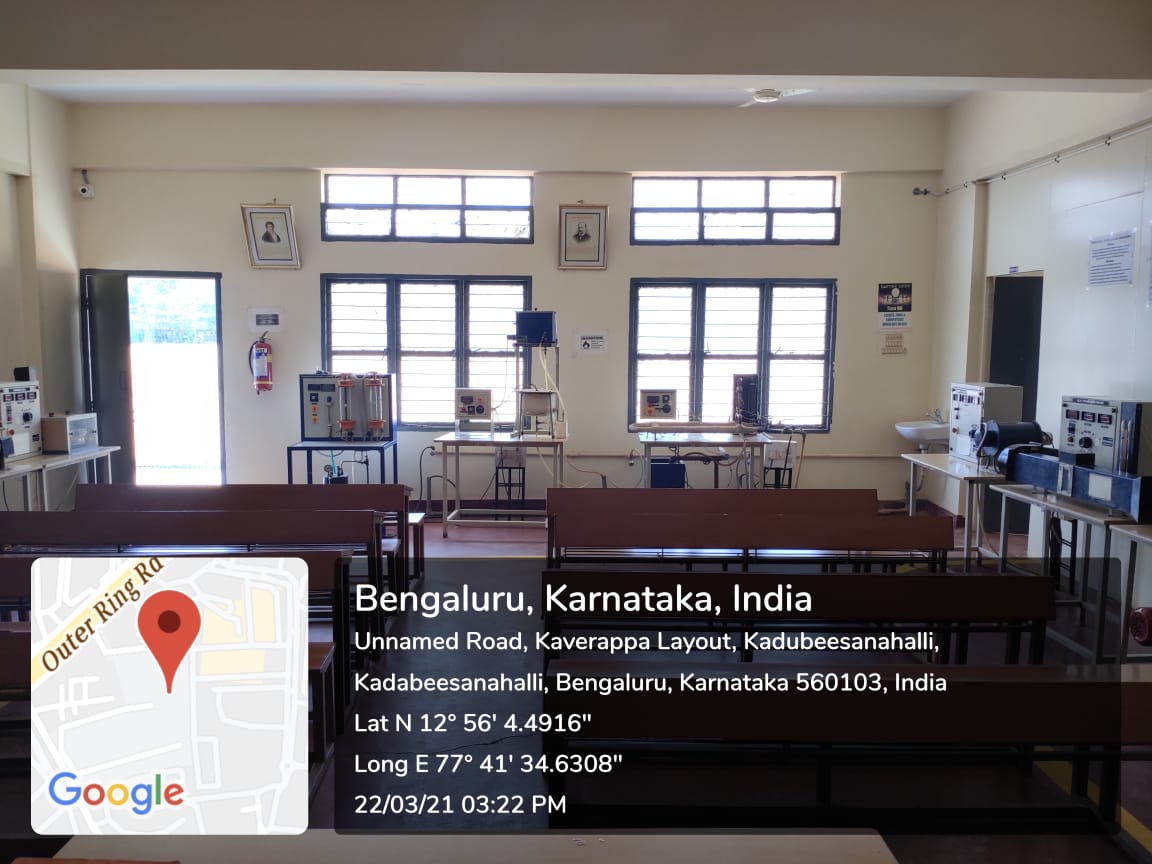

CLASS ROOMS

B-301

B-302

B-303

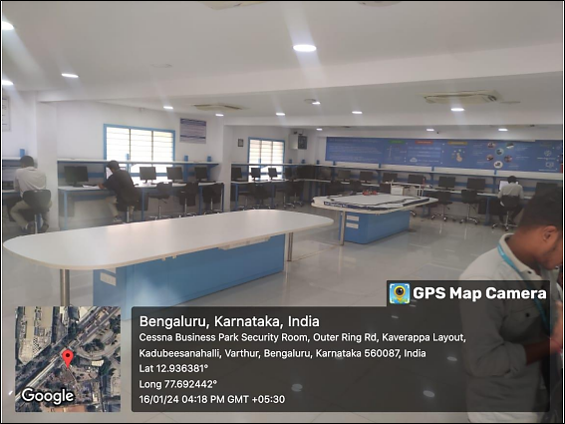

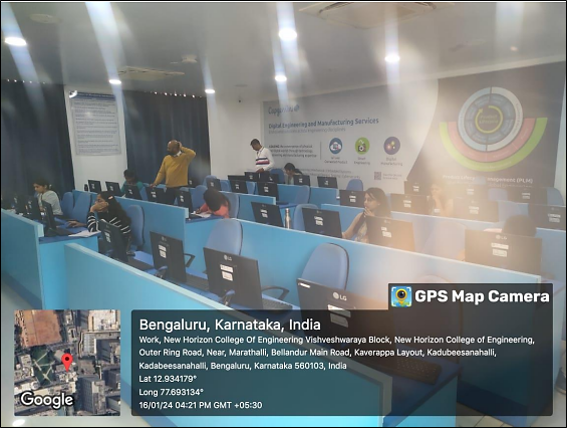

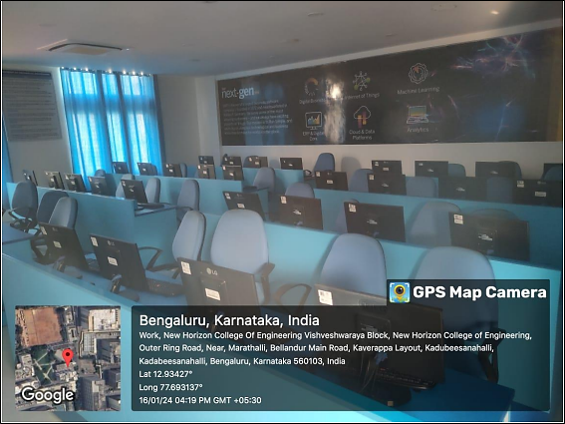

PLM-DEMS Lab

SAP Lab